Is your herbal medicine this pure and this effective?

Please take the time to read about the importance of choosing the right herbal medicinals because

Not All Herbs Are the Same…

Working with herbs to consistently manufacture high quality products is not easy as plants are naturally complex and the quality of a finished product can vary enormously, presenting MediHerb with continual challenges. These challenges are numerous, and include the inherent biological and chemical variability of herbs, the influences on quality of growing, harvesting, drying and storage, extraction of the herb, stability and the ultimate problem of defining quality in a meaningful way.

Not all herbs contain the same levels of active constituents. Not all herbs are grown or harvested or dried or stored in the same way. Not all herb growers', suppliers', or manufacturers' standards are the same and not all methods to determine quality are the same. We have worked with herb growers to provide technical assistance on how to grow better quality plants that meet rigorous international standards.

MediHerb is so strict in its medicinal guidelines that it has rejected some herb supplies worldwide for up to a year. They have also been at the forefront of identifying "species substitution" which is a common cost-saving strategy that many herb suppliers use. Tribulus is a good example because pure Bulgarian Tribulus has a cost many times more than typical Chinese or Indian substitutions.

MediHerb Product Supply & Testing

MediHerb of Australia

Here at Conscious Body we work with many serious illnesses and conditions. We rely on herbs that are lab-tested and meet international standards. That is why we choose MediHerb of Australia based in a beautiful agricultural area of Queensland. In their pharmaceutical GMP manufacturing facility they produce a large range of herbal products in liquid extracts and tablets. MediHerb is unique in the amount of research and quality control that is present in every herbal produce produced. Their commitment to rigorous sourcing and testing of herbs and the actual development of manufacturing and extraction processes have revolutionized the herbal products industry. They have raised the bar of herbal purity and quality.

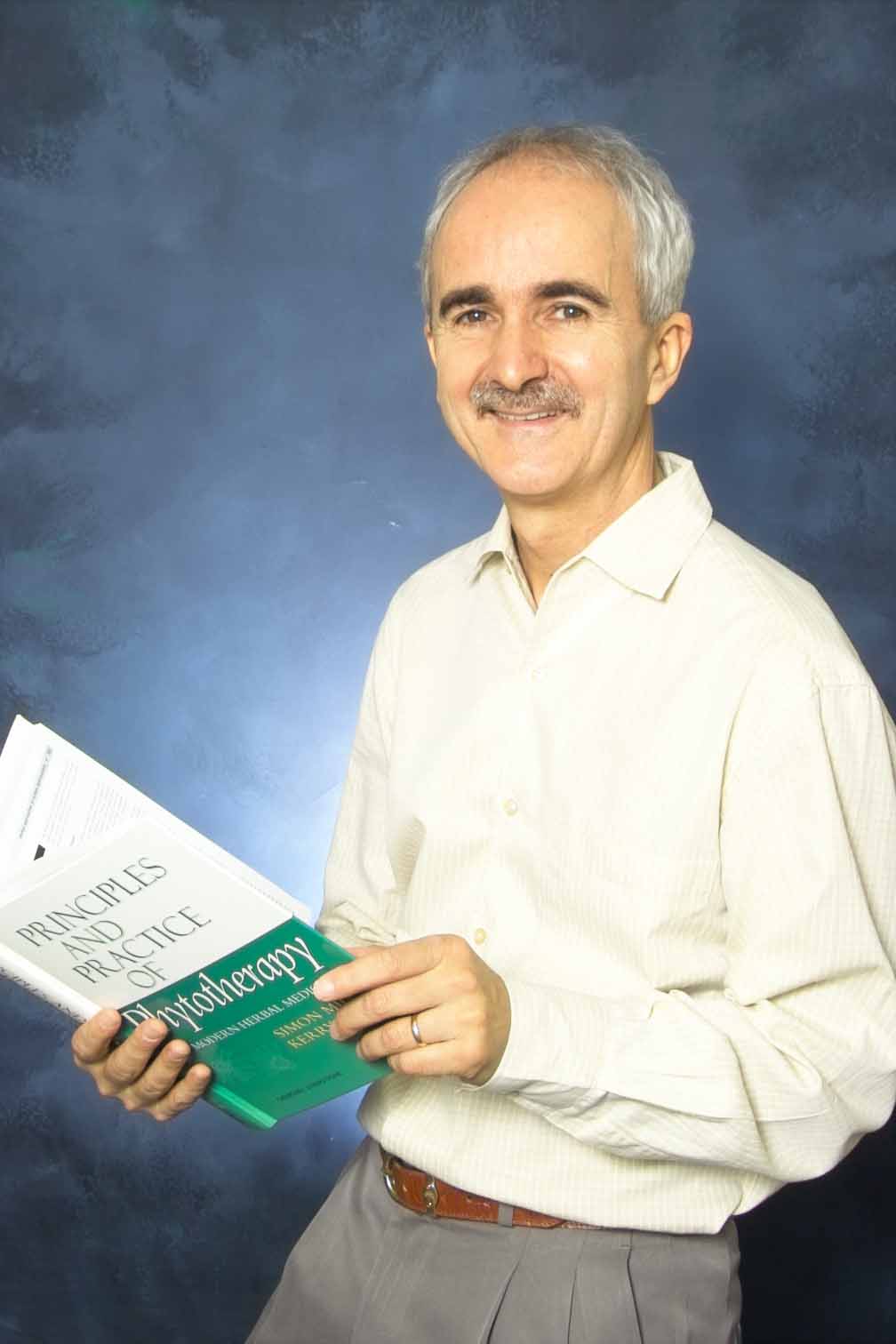

Dr. Kerry Bone, Founder of MediHerb has been internationally recognized for his clinical research into the immunological effects of Echinacea Purpurea. He has also published the world’s leading Herbal Clinical Text.

See the gardens, the labs and the philosophy of MediHerb of Australia.

Endangered Herbal Species

Wherever possible we aim to source organically grown and wildcrafted herbs, and also work with growers to help cultivate endangered species,

for example Golden Seal. We are very fortunate in Australia to have healthy soils and a wonderful climate for herb growing, so many of the herbs used in MediHerb products are from local growers. We also source herbs from overseas where the climatic conditions and specific handling requirements are the optimum, for example Devil’s Claw from the Kalahari Desert and Cat’s Claw from Peru. It is particularly important for these indigenous communities who depend on the income of the herb crops for their well-being that they understand the quality issues and how best to grow or sustainably harvest the herb. Together we can ensure that they will sell their crops and provide income for their community.

Dr. Kerry Bone, PhD, Founder of MediHerb of Australia and the most recognized published author and researcher on the use of herbs in clinical medicine.

“For every human illness, somewhere in the world there exists a plant which is the cure. I believe that there is a healing potential locked inside plants which is integral with their evolution, just as it is part of human evolution to learn to tap this wonderful gift of Nature”

MediHerb's Patented Extraction Process for the Perfect Herb

MediHerb has developed a unique and patented process of extracting using a Cold Percolation method. This is unlike other herbal extraction processes; no heat or concentration are used, both of which may cause damage to the delicate plant material. The greatest care is taken to prevent any contamination from outside sources throughout the extraction process.

MediHerb prefers to use high quality dried herbs in making extracts rather than fresh herbs. Fresh herbs have a high water content, up to 80% and this makes for a weaker extract. In addition to the herb itself, they use only two other raw materials in manufacturing our herbal extracts, ethanol and purified water. Both are chosen very carefully to ensure the most efficacious product and meet pharmaceutical standard specifications.

All process water used in extraction is purified by reverse osmosis and the ethanol complies with the British Pharmacopoeia specification for ethanol. Ethanol is essential to extract the full phytochemical profile of the plant which cannot be achieved using water or glycerol alone. Ethanol has been used for hundreds of years in herbal extraction and old herbal texts discuss steeping herbs in wine over long periods. It is perfectly safe since the human liver is naturally conditioned to metabolize small amounts of ethanol from ripe fruit and naturally fermented food.

“Our passion at MediHerb is to unlock the healing power of plants by combining the time-honored wisdom of traditional knowledge with sound clinical experience and the rigor of scientific research. This quest can only be attained by the total commitment to quality and continuous improvement, which permeates every aspect of our endeavors”

Dr. Kerry Bone was internationally recognized for his research into the immunological effects of Echinacea Purpurea.